Wheatheart 10" & 13" Swingaway Auger Manual

Share on Social Networks

Share Link

Use permanent link to share in social mediaShare with a friend

Please login to send this document by email!

Embed in your website

6. 1. I NTRODUCTION W HEATHEART - SA A UGERS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 6 4504156 R6

14. 2. S AFETY F IRST W HEATHEART - SA A UGERS 2.6. S AFETY D ECAL L OCATIONS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 14 4504156 R6

26. 4. O PERATION W HEATHEART - SA A UGERS 4.4. O PERATION P ROCEDURE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 26 4504156 R6

1. Part Number: 4504156 R6 Revised: Mar/10 Read this manual before using product. Failure to follow instructions and safety precautions can result in serious inju ry, death, or property damage. Keep manual fo r future reference. SA AUGERS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 OPERATION AND PARTS MANUAL

36. 6. S TORAGE W HEATHEART - SA A UGERS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 36 4504156 R6

42.

25. W HEATHEART - SA A UGERS 4. O PERATION SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4.4. O PERATION P ROCEDURE 4504156 R6 25 Figure 4.3 Power Swing/Hydraulic Winch Option Figure 4.3 Control Valve

44. Wheatheart is a Division of Ag Growth Industries LP Part of the Ag Growth International Inc. Group P.O. Box 39 Rosenort, Manitoba, Canada R0G 1W0 Phone: (866) 467- 7207 (Canada & USA) Fax: (866) 768-4852 website: www.wheatheart.com email: sales@wheatheart.ca © Ag Growth Industries Limited Partnership 2009 Printed in Canada

12. 2. S AFETY F IRST W HEATHEART - SA A UGERS 2.6. S AFETY D ECAL L OCATIONS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 12 4504156 R6 Figure 2.3 DECAL #17098 DECAL #17097 DECAL #17096 DECAL #17102 DECAL #17101 DECAL #27709

13. W HEATHEART - SA A UGERS 2. S AFETY F IRST SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 2.6. S AFETY D ECAL L OCATIONS 4504156 R6 13 Figure 2.4 PLACED ON MACHINE BEHIND GUARD DECAL #17099 DECAL #17107 DECAL #18859 DECAL #19960 DECAL #17531 DECAL #17098 DECAL #17101 DECAL #27709 DECAL #17094

38. 7. T ROUBLESHOOTING W HEATHEART - SA A UGERS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 38 4504156 R6 Auger will not stay in elevated position. Leak in auger hydraulic cylinder or fittings. Identify and repair leak. Leak in tractor hydraulics. Close hydraulic valve to isolate cylin- der from tractor hydraulics. Tube is misaligned. Loose truss cables. Tighten cables as required. Table 7.1 PROBLEM CAUSED BY SOLUTION

5. W HEATHEART - SA A UGERS 1. I NTRODUCTION SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4504156 R6 5 1. Introduction Congratulations on the purchase of your new W heatheart SA Auger. This equipment will complement your agricultural operation by safely and efficiently moving grain, pulse crop s, fertilizer, and any other granular materials. Many of the features incor porated into this machine are the result of suggestions made by customers like like. Your new Wheathea rt auger will serve you well if you understand how it operates, and if you use it and care for it properly. This manual is intended to help you lear n how to operate and maintain your equipment in a safe, effi cient, and trouble-free manner. Please read this manual before you use your new grain auger. This manual covers all SA augers built by Wheatheart Manufacturing. Use the table of contents as a guide when searching for specific information. Keep this manual in a safe place for future refe rence and for ordering replacement parts. Should any information rema in unclear after thoroughly reviewing this manual, contact your Wheatheart Dealer for clarification before operating your auger. Knowing the serial number and date of purchase will save time in getting your questions answered. Please write down this informatio n in the space provided below.

9. W HEATHEART - SA A UGERS 2. S AFETY F IRST SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 2.2. O PERATING S AFETY 4504156 R6 9 • Follow good shop practices: • keep service area clean and dry • be sure electric al outlets and t ools are properly grounded • use adequate light for the job at hand • Think SAFETY! Work SAFELY! 2.2. OPERATING SAFETY • Ensure guards are installed and secure. • Clear the work area of untrained peo- ple. • Clean the work area to prevent slip- ping or trip- ping. • Have a fully equipped first aid kit and fire extinguisher on hand and know how to use them. • Be certain the PTO driveline is securely attached to the auger and to the tractor. • Before start- ing the tractor, be certain that the PTO is in the off posi- tion. • Keep hands, feet, hair, and clothing away from all mov- ing or rotating parts. Figure 2.1

2. This product has been designed and constructed accordi ng to general engineering standards a . Other local regulat ions may apply and must be followed by the operator. We strongly recommend that al l personnel associated with th is equipment be trained in the correct operational an d safety procedures required for this product. Periodic reviews of this manual wit h all employees should be st andard practice. For your convenience, we include this sign-off sheet so you can record y our periodic reviews. a. Standards include organizations such as the American Society of Agri cultural and Biological Engineers, American National Standards Institute, Canadian Sta ndards Association, International Organization for Standardization, and/or others. Date Employee Signature Employer Signature

4. TABLE OF CONTENTS W HEATHEART - SA A UGERS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4 4504156 R6 5. Maintenance......... ................ ................. ................ .............. .............. .............. ............. ....... 27 5.1. Fluids and Lubricants ............... ................ ................ ................. ................ ............. 27 5.2. Maintenance Intervals ........... .............. .............. .............. ............... .............. .......... 27 5.3. Maintenance Procedures............ ................ ................. ................ ................. .......... 28 5.3.1. Visual Inspection ................ ................ ................ ............... .............. .......... 28 5.3.2. Hydraulic Hose and Coupler Inspection .. .................. ........... ............ ........ 28 5.3.3. Machine Greasing........... ................. ................ ................. .............. .......... 29 5.3.4. Hopper Lift Cable Inspecti on ............. ................ ............... .............. .......... 30 5.3.5. Winch and Pulley Servicing .......... ................. ................ ................. .......... 30 5.3.6. Boot and H opper Chain Drive Servicing ............ ............... .............. .......... 30 5.3.7. Gearbox Oil Level ........... ................. ................ ................. .............. .......... 31 5.3.8. Machine Cleaning ........... ................. ................ ................. .............. .......... 32 5.3.9. Tire Pressure C heck .............. .............. .............. ............... .............. .......... 32 5.3.10. Wheel Bearings Repack .................... .............. ............... .............. .......... 32 5.3.11. Wheel Bolt Tight ening................. ................. ................ ................. .......... 32 5.3.12. Cable Tightening.... .............. .............. .............. ............... .............. .......... 32 5.3.13. Gearbox Oil........ ................ ................ .............. ............... .............. .......... 34 6. Storage ............... ................ ................ .............. .............. .............. ............... ............. ........... 35 7. Troubleshooting .............. ................ ................ ................. ................ ................. ............. .... 37 8. Appendix .............. ................ ................. .............. .............. .............. .............. ............. ......... 39 8.1. Specifications .......... ................. ................ ................ ................. ................ ............. 39 Warranty Registration...... ................ .............. .............. .............. ............... .............. ............ ..... 41 Limited Warranty ............. ................ ................. ................ ................ ................. ............... ....... 43

37. W HEATHEART - SA A UGERS 7. T ROUBLESHOOTING SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4504156 R6 37 7. Troubleshooting The following table lists the causes and so lutions to some po tential problems you may encounter in operati ng your swing-away auger. Table 7.1 PROBLEM CAUSED BY SOLUTION The auger does not turn. Auger is plugged or obstructed. Identify and remove obstruction. A bearing has seized. Identify the bearing and replace. A chain is broken. Identify the chain and repair or replace. The gearbox has seized. Fix or replace the gearbox. Gearbox coupler bolt is broken or missing. Replace the bolt. PTO shear bolt has failed. Replace the bolt. The upper auger sec- tions will not turn. The coupler bolt below the non- rotating section is broken or miss- ing. Replace the bolt. Auger is noisy. Obstruction in the auger. Identify and remove obstruction. Flighting shaft bolts are loose or damaged. Tighten or replace bolts. Auger shaft is bent. Repair or replace shaft. Flighting is damaged. Repair or replace flighting. Worn bearing. Repair or replace bearing. Low gear oil level. Inspect the gearbox and repair or replace if damaged. If no damage is found, add oil to gearbox. Tube is misaligned. Adjust truss cables. The auger will not raise or lower. Closed hydraulic valve. Open hydraulic valve. Inadequate hydraulic pressure. Adjust the pressure if possible, or use an alternate hydraulic supply. Damaged cylinder. Fix or replace the cylinder. Missing or broken cylinder pin. Replace cylinder pin. Hydraulic system leak. Identify and repair leak. Auger movement is obstructed. Identify and clear the obstruction. Low material augering rate. Tractor PTO speed is too slow. Increase engine rpm. Inadequate material flow from truck or hopper. Increase flow of material. Flow into the auger hopper is restricted. Clear grating of obstructions. Material is too wet or heavy. Unloading rates are for dry grain. Flighting is worn. Repair or replace as required.

40. 8. A PPENDIX W HEATHEART - SA A UGERS 8.1. S PECIFICATIONS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 40 4504156 R6 Table 8.2 Imperial Bolt Torque BOLT DIAMETER (Nm) (Lb-ft) (Nm) (Lb-ft) (Nm) (Lb-ft) 1/4" 8 6 12 9 17 12 5/16" 13 10 25 19 36 27 3/8" 27 20 45 33 63 45 7/16" 41 30 72 53 100 75 1/2" 61 45 110 80 155 115 9/16" 95 60 155 115 220 165 5/8" 128 95 215 160 305 220 3/4" 225 165 390 290 540 400 7/8" 230 170 570 420 880 650 1" 345 225 +850 630 1320 970 Table 8.3 Metric Bolt Torque BOLT DIAMETER (Nm) (Lb-ft) (Nm) (Lb-ft) M3 0.5 0.4 1.8 1.3 M4 3 2.2 4.5 3.3 M5 6 4 9 7 M6 10 7 15 11 M8 25 18 35 26 M10 50 37 70 52 M12 90 66 125 92 M14 140 103 200 148 M16 225 166 310 229 M20 435 321 610 450 M24 750 553 1050 774 M30 1495 1103 2100 1550 M36 2600 1917 3675 2710

19. W HEATHEART - SA A UGERS 4. O PERATION SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4.1. D ESCRIPTION OF THE E QUIPMENT 4504156 R6 19 4. Operation 4.1. DESCRIPTION OF THE EQUIPMENT Your auger comes field r eady and equipped with such feat ures as single acting hydraulics, inward folding scissor lift fo r superior reach, a low profile hopper, reinforced flighti ng in the hopper and incline t ube, an enhanced grain pickup system, left or right han d hopper operation, 6 bolt automotive hubs, handy service access doors, and a constant velocity (CV) PTO shaft. Warning: Before continuing, please re read the safety information re levant to this section at the beginning of this manual. Failure to follo w the safety instructions can result in serious injury, death, or property damage.

29. W HEATHEART - SA A UGERS 5. M AINTENANCE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 5.3. M AINTENANCE P ROCEDURES 4504156 R6 29 5.3.3. M ACHINE G REASING Important: Most original equi pment bearings used by Wheat heart are sealed units and will not accept grease. There are 8 grease fittings on the machine (shown in Figure 5.1): • 1 at the upper f lighting bearing (A) • 3 on the intake hopper—2 bushings (B) and 1 at the U-joint (C) • 1 at the u-joint between gearboxes (D) • 1 at the lower fl ighting bearing (E) • 5 on the PTO (F) Figure 5.1 Grease Fitting Locations To grease: 1. Use Use SAE multi-purpose high-temper ature grease with extreme pressure (EP) performance or SAE multi-purpose lithium-based grease. 2. Use a hand-held grease gun only. 3. Wipe grease fitting with a clean cloth before greasing to avoid injecting dirt and grit. 4. If a fitting will not take grease, remove and cl ean thoroughly. Also clean lubricant passageway. Repl ace fitting if necessary. 5. Replace and repair brok en fittings immediately.

34. 5. M AINTENANCE W HEATHEART - SA A UGERS 5.3. M AINTENANCE P ROCEDURES SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 34 4504156 R6 5.3.13. G EARBOX O IL 1. Place a pan under the drain plug. 2. Use a wrench and re move the drain plug. 3. Loosen the filler plug so air can enter the gearbo x and the oil will drain freely (see Figure 5.5). 4. Allow the oil to drain completely. 5. Replace the drain plug. 6. Add oil until the gearbox is half full (c enter of cross shaft) and replace filler plug. A flexible funnel may be required. Gearbo x should be level when checking or refilling. Do not overfill . For more extensive servicing or repa irs, remove the ho pper from the boot assembly by removing the 3/ 8” x 3/4” bolts and large washers. Lift the gearbox end with a front end lo ader or other secure method as shown in Figure 5.8. The hopper end should remain on the ground. Wh en reassembling, lightly grease the splined shaft and check and retighten setscrews and connecting bolts. Figure 5.8 Hoppe r Tube Removal

28. 5. M AINTENANCE W HEATHEART - SA A UGERS 5.3. M AINTENANCE P ROCEDURES SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 28 4504156 R6 5.3. MAINTENANCE PROCEDURES 5.3.1. V ISUAL I NSPECTION Before beginning visual in spection, check auger wheel s and ensure that all operators are awayre of safety procedures. When inspecting, look for possi ble defects and for the following: • Be sure all guards are in pl ace, functioni ng, and not damaged. • Make sure access, servic e, and cleanout covers ar e in place and secure. • Check that all hardware is in place and secure. • Inspect hydraulic hoses and fittings for leaks and wear . Fix or replace where necessary. • Inspect around the machine for evidence of hydraulic leaks. • Examine flighting for da mage or unusual wear. • Inspect the truss cables for proper tension and possible damage such as fraying, kinki ng, or unwinding. • Inspect hopper winch cable fo r fraying, kinking, unw inding, or other possi- ble damage. • Examine tires for gashes, uneven we ar, or loss of air pressure. • Be sure all safety decal s are in place and legible. • Check the PTO shield & replace if damaged. 5.3.2. H YDRAULIC H OSE AND C OUPLER I NSPECTION Using a piece of cardboar d or wood, run it along the length of the hose and around all fittings. Replace th e hose or tighten/replace the fitting if a leak is found. WARNING High-pressure hy draulic fluid! Escaping oil under pre ssure can penetrate the skin and cause serious injury. • Relieve pressure on system before repair- ing, adjusting, or disconnecting. • Keep connections tight and components in good repair. • Use a piece of wood or cardboard when searching for leaks. DO NOT use your hand. • Seek medical attent ion immediately if ANY hydraulic fluid penetrates your skin.

43. LIMITED WARRANTY Wheatheart warrants to t he buyer that the new machinery is free from defects in material and workmanship. This warranty is only effective for any new machinery that has not been altered, changed, repaired, or treated sinc e its delivery to the bu yer, other than by Wheatheart or its authorized dealers or employees, and does not apply to accessories, attachment s, tools, or parts sold or operated with the new machiner y if they have not been ma nufactured by Wheatheart. Wheatheart shall only be liable for defects in the material or wo rkmanship attributed to faulty material or bad workmanship that can be proved by the buyer, and specifically excludes liability for repairs arising as a result of normal wear and tear of the new machinery or in any other man- ner whatsoever, and without limiti ng the generality of the foregoing, exclude s application or installation of parts not completed in accord ance with Wheatheart oper ation manual, specifica- tions, or printed instructions. A Warranty Registration Fo rm and Inspection Repor t must be completed at the time of delivery and returned to Wheatheart Manufacturi ng within thirty (30) days. Warranty Period Defective parts are subject to inspection by a Wheatheart represent ative prior to approval of a warranty claim. All returned parts mu st be sent to the fa ctory, freight pre-paid , in order to qualify for warranty replacement. Re paired or replaced parts will be returned freight collect. If these conditions are fulfilled, Wheatheart shall at its own cost and its own option either repair or replace any defective parts provided that t he buyer shall be responsible for all expenses incurred as a result of repairs, labor, parts, tr ansportation, or any other work, unless Wheatheart has authorized such expenses in advance. No rmal wear and service it ems such as belts, hoses, flashing, etc. ar e excluded from warranty. The warranty shall not extend to any repairs, changes, alterations, or replacements made to the new equipment other than by Wheatheart or its authoriz ed dealers or employees. This warranty extends only to the or iginal owner of the new equipment. This warranty is limited to the terms stated herein and is in lieu of any other warranties whether expressed or implied, and withou t limiting the generalit y of the foregoing, excluded all warran- ties, expressed or implied, or conditions whether statut ory or otherwise as to quality and fitness for any purpose of the new equipment, Wheatheart disclaims al l liability for incidental or conse- quential damages. This machine is subject to design changes and Whea theart shall not be requ ired to retro-fit or exchange items on previo usly sold units exc ept at its own option. WARRANTY VOID IF NOT REGISTERED Private Farm Use One (1) year from date of purchase. Commercial, Custom, or Rental Use Ninety (90) days from date of purchase. Replacement Parts Ninety (90) days from date of replacement

3. TABLE OF CONTENTS W HEATHEART - SA A UGERS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4504156 R6 3 1. Introduction .............. ................ ................. ................ ................ ................. ................ .......... 5 2. Safety First.............. ................ ................ ................. ................ ................. ................ ............ 7 2.1. General Safety .... ................ ................. ................ .............. .............. .............. .......... 8 2.2. Operating Safety ........ ................ ................. ................ ................. ................ ............ 9 2.3. Transport Safety ......... ................ ................. ................ ................. ................ .......... 10 2.4. Storage Safety.......... ................ ................ ................. ................ ................. ............ 10 2.5. Maintenance Safety...... ................. ................ ................ ................. .............. .......... 10 2.6. Safety Decal Locations ............... ................. ................ ................. ................ .......... 11 2.6.1. Decal Installation .......... ................. ................ ................. ................ .......... 11 2.6.2. Decal Locations ............ ................. ................ ................. ................ .......... 11 3. Transport & Placement ..... ................. ................ ................ ................. ................ ............... 15 3.1. Transport Procedure ................ ................ ................. ................ ................. ............ 15 3.2. Placement Procedure ............... ................ ................. ................ ................. ............ 17 4. Operation .................. ................ ................. ................ ................ ................. ............... ......... 19 4.1. Description of the E quipment ............... .............. .............. .............. .............. .......... 19 4.2. Operator Controls ..... ................ ................ ................. ................ ................. ............ 20 4.3. Pre-Operation ........... ................ ................ ................. ................ ................. ............ 20 4.3.1. Checklist ............ ................ ................ ................. .............. .............. .......... 20 4.3.2. PTO Drive .......... ................ ................ ................. .............. .............. .......... 20 4.3.3. Hydraulics .......... ................ ................ ................. .............. .............. .......... 21 4.4. Operation Procedure .... ................. ................ ................ ................. .............. .......... 22 4.4.1. Initial Start-Up .... ................ ................ ................. .............. .............. .......... 22 4.4.2. Operating With a Full Load ................ ................. .............. .............. .......... 23 4.4.3. Shutdown............. ................ ................. .............. .............. .............. .......... 23 4.4.4. Lowering & Completion ..... ................ ................. .............. .............. .......... 24 4.4.5. Power Swing / Hydraulic Winch Option ......... ................. ................ .......... 24

18. 3. T RANSPORT & P LACEMENT W HEATHEART - SA A UGERS 3.2. P LACEMENT P ROCEDURE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 18 4504156 R6 Note: Do not place anything under the whee ls of the auger for added height. 6. Check that the valve on the cylinder hose is open to raise the auger and closed once the auger is in position. 7. Chock auger wheels on both sides and apply the tr actor’s parking brake before using the auger to mo ve product (Figure 3.6). 8. When operating the auger in the raised position, re st the discharge end on the bin roof or tie it down to the bin to preven t upending or the wind fromup- setting the auger. When oper ating the auger in a free-standing position, anchor the intake end. 9. Fully lower the hopper to the ground and remove the lift cabl e from the hopper. Note: When raising or lowering th e auger, the inta ke hopper must be lifted off the ground. Figure 3.6 Auger Placement CAUTION If hose valve remains open, a loss of hydraulic pressure within the trac tor system will allow the auger to lower inadvertently, damaging equipment and/or causing personal injury.

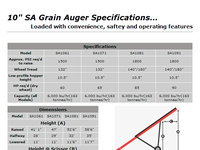

39. W HEATHEART - SA A UGERS 8. A PPENDIX SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 8.1. S PECIFICATIONS 4504156 R6 39 8. Appendix 8.1. SPECIFICATIONS Important: Wheatheart Manufacturi ng reserves the right to c hange specifications without notice. Bolt Torque Values The tables shown below give correc t torque values for various bolts and capscrews. Tighten all bolts to the tor que specified in the ch art unless otherwise noted. Check tightness of bo lts periodically, using bolt torque chart as your guide. Replace hardware with t he same strength bolt. Torque figures indicated above are valid for non-greased or non-oiled threads and head unless otherwise specified. Therefore, do not grease or oil bolts or capscrews unless otherwise specified in this manual. When using locking elements, increase torque values by 5%. Table 8.1 1061 1071 1081 1091 1371 1381 1391 CAPACITy Unloading Rate 5400 - 6000 Bu/Hr 8700 - 9600 Bu/Hr DIMENSIONS Tube Size 10” 10” 10” 10” 13” 13” 13” Transport Length 63’5” 73’6” - - - - - Width 11’ 11’ 11’8” / 15’ 11’8” / 15’ 11’8” / 15’ 11’8” / 15’ 11’8” / 15’ Height 12’11” 12’11” 13’6” 13’6” 12’1” 11’8” 12’4” Discharge Clearance Min 11’ 11’ 11’6” 11’7” 9’9” 9’3” 9’11” Max 41’1” 47’ 52’6” 58’6” 49’ 53’9” 61’3” Reach to Wheels Min 23’5” 26’10” 29’2” 35’5” 26’9” 29’1” 30’1” Max 29’6” 34’2” 39’3” 45’ 35’9” 42’ 45’2” TIRES Type Type 15” Bias Ply 16” Bias Ply Inflation Pressure 18 – 24 psi Hubs 6 Bolt Automotive Type WEIGHT Total Weight 3100 lb 3410 lb 3980 lb 5010 lb 4915 lb 5550 lb 6745 lb est. PTO DRIVE Power Requirements 60 HP 65 HP 80 HP 90 HP 100 HP 120 HP 140 HP PTO Speed 540 rpm PTO Shaft 14R Constant Velocity w/ Shear 35R OTHER Hitch Jack 2000 lb Side Winder

16. 3. T RANSPORT & P LACEMENT W HEATHEART - SA A UGERS 3.1. T RANSPORT P ROCEDURE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 16 4504156 R6 6. Open the hose va lve and then use the tractor valve to lower the auger. Feather the lever to prevent too rapid a descent. Lower the auger until the transport brace is fully seated (Figure 3.1). 7. Raise intake feed hopper into transport position and secure with saddle pin and hairpin (Figure 3.2). a. Lock in transport pos ition with the handle on the side of the hopper. b. Attach cable hook to the loops inside the hopper. c. Fully raise hopper with intake side facing away from t he main auger as shown. d. Secure hopper to lift arm with the hopper lock, saddle pins, and hairpins provided.Retract th e wheels prior to transporting (1081, 1091, and 13” models only). 8. Install the safety c hain between the auger and the fr ame of the towing unit. The chain must have a load rating at least as high as the auger weight. a. Thread safety chain through the auger hitch and bolt together before attaching to the towing vehicle. The lo op should form a cradle that will prevent the auger from digging into the road surface and upsetting it, should a breakaway occur. NOTICE Transporting with axles ex tended may cause equipment damage and may be in violation of local transport regulations. Figure 3.1 Transport Brace Figure 3.2 Intake Hopper in Transport Figure 3.3 Auger Chained to a Vehicle Note:

11. W HEATHEART - SA A UGERS 2. S AFETY F IRST SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 2.6. S AFETY D ECAL L OCATIONS 4504156 R6 11 2.6. SAFETY DECAL LOCATIONS • Keep safety decals clean and legible at all times. • Replace safety decals that are missing or have become illegible. See decal location figures below. • Replaced parts must display the same decal(s) as t he original part. • Safety decals are available from y our distributor, dealer, or factory. 2.6.1. D ECAL I NSTALLATION 1. Decal area must be clean and dry, wi th a temperature above 10°C (50°F). 2. Decide on the exact position bef ore you remove the backing paper. 3. Align the deca l over the specified area and carefully press the small portion with the exposed sti cky backing in place. 4. Slowly peel back the remaining paper and carefu lly smooth the remaining portion of the de cal in place. 5. Small air pockets can be pierced with a pin and smoothed out using the sign backing paper. 2.6.2. D ECAL L OCATIONS Replicas of the safety decals that are attached to the equipment are shown below. Good safety requires t hat you familiarize yourself with the various safety decals and the area s or particular functions that the decals apply to as well as the safety precautions that must be taken to avoid se rious, injury, death, or damage. Figure 2.2 DECAL #17100

20. 4. O PERATION W HEATHEART - SA A UGERS 4.2. O PERATOR C ONTROLS SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 20 4504156 R6 4.2. OPERATOR CONTROLS The hopper winch is located as shown in Fi gure 4.1. The hydrau lic shut-off valve is located as shown in Figur e 4.2. Please refer to t he tractor manual for hydraulic and PTO controls. 4.3. PRE-OPERATION 4.3.1. C HECKLIST • Tighten all fasteners. • Adjust and/or lubricate boo t chain and hopper chain. • Ensure auger rotates freely. • Check that tire pressure is with in the manufacture r’s specification. • Ensure wheel bolt torque is within specification . • Check hopper winch cable fo r damage (fraying, kinki ng, unraveling). Replace as required. • Ensure cable anchor on t he winch drum is tight. • Check gearbox oil levels. • Grease and clean machine if needed. • Ensure hydraulic system is functioning, is free of le aks, and the hoses are not pinched or kinked. • Check that truss cables are free from damage (fraying, kinkin g, unraveling). The cables must be tight and properly adjus ted for proper auger tube align- ment. • Ensure PTO shaft is properly installed. 4.3.2. PTO D RIVE Correct operation of the Wheatheart SA auger require s pre-inspection of the drive system, operator knowledge on how to shut down the system, and a general monitoring of the system during operation. Figure 4.1 Winch Location Figure 4.2 Shut-off Valve

35. W HEATHEART - SA A UGERS 6. S TORAGE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4504156 R6 35 6. Storage To ensure a long, trouble-free life, the following procedure should be followed when preparing the unit for storage after the season’s use: 1. Fully lower the auger. 2. Remove all residual material from the auger. 3. Remove entangled material from all moving or rotating parts. 4. Wash the entire machi ne thoroughly using a water hose or pressure washer to remove all dirt, mud, debris, and residue. 5. Repair or replace any worn or damaged co mponents to prevent any unnecessary downtime at the start of the next season. 6. Touch up all paint nicks and scratches to prevent rusting. 7. Position the auger in an area that is dry, level, free of debris, and away from human activity. 8. Support the hitch on blocks to elim inate prolonged contac t with the ground. 9. Lubricate all grease fittings (see page 29). 10. Clean and lightly lubricat e the spline on the PTO dr iveline. Cover the PTO driveline with a plasti c bag to protect it from the weather and plac e it in the transport saddle. 11. Check tire pressure and inflate to 24 psi (165 kPa). 12. Chock the wheels. 13. Place the hopper in tr ansport position, ensuring there will be adequate drainage of any moisture. Warning: Before continuing, please re read the safety information re levant to this section at the beginning of this manual. Failure to follo w the safety instructions can result in serious injury, death, or property damage. WARNING To reduce the risk of inju ry or death, store in an area away from hum an activity and do not permit children to play on or around the stored machine.

21. W HEATHEART - SA A UGERS 4. O PERATION SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4.3. P RE -O PERATION 4504156 R6 21 G ENERAL I NFORMATION Before starting the auger, ensure that: • The PTO driveline is secu rely attached to the auger shaft and to the tractor. • The PTO driveline rotating shield is in place and in goo d working order. • The PTO does not exceed the ma ximum operating angle of 15°. • All safety shields are in place and secure on both the tractor and the auger. • The PTO drive on the tractor is in the off position before starting the tractor. • The auger-to-tractor PTO hookup distances are set as specified in the decal on the PTO shield of the auger. • Everyone is clear of the PTO hazard area. Note: If shear bolt in the PTO dr iveline fails, shut down a nd lock out the tractor to replace the bolt. Use a 5/16” x 1” GR 8 bolt. Ensure the s hear point is through the shank of the bol t, not the threads. L OCKOUT 1. Shut down the tractor and remove the ignition key or coil wire. 2. If step 1 is not possible, remove the PTO driveline from the tractor. 4.3.3. H YDRAULICS Before using the hydr aulics, ensure that: • The quick connect couplers on both the auger and the trac tor are clean and free of dirt. Wipe the couplers with a clean, dry cloth. • The hydraulic hoses are pr operly connected and secur ed; are free of leaks, wear, and binding; and are rout ed away from moving parts. • Hydraulic pressure has been re lieved prior to disconnecting.

30. 5. M AINTENANCE W HEATHEART - SA A UGERS 5.3. M AINTENANCE P ROCEDURES SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 30 4504156 R6 5.3.4. H OPPER L IFT C ABLE I NSPECTION Check the cable for damage su ch as fraying, kinking, or unwinding. Replace if damaged. To replace: 1. Unwind the winch drum and remove the cable clamps. 2. Free the cable from the winch and pulleys. 3. Remove the cable clamps t hat secure the hook in place. 4. Reverse the above steps to install the new cable. 5.3.5. W INCH AND P ULLEY S ERVICING • Ensure the cable is slack before servicing the winch. • Check to make sure cable clamps are secure. • Keep a film of grease on the gears. Occasionally oil the bushings, drum shaft, and ratchet. • Oil cable pulleys needed (Figure 5.2) 5.3.6. B OOT AND H OPPER C HAIN D RIVE S ERVICING Figure 5.2 Cable Pulleys DANGER Rotating parts hazard: • Fingers, hands, feet , hair, clothing, and accessories can become caught or drawn into the pinch point. • Shut off and disable power source before adjusting or servicing. • DO NOT operate with guards removed or modified. • Keep away from rotating parts. • Tie up long hair and remove jewelry. • DO NOT wear loose- fitting clothing or items that could become caught.

33. W HEATHEART - SA A UGERS 5. M AINTENANCE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 5.3. M AINTENANCE P ROCEDURES 4504156 R6 33 • There is no slack in the cables. T IGHTENING C ABLES The location of the cable adjustm ent eyebolts are shown in Figure 5.7. Note: The 1061 only has a long cable. 1. Lift the disc harge end of the auger with a front end loader or rest on a bin so that the tube has a slight upward deflection at the discharge to give the cable some slack. 2. Tighten the nut on the eyebolt to in crease the tension in the cable. 3. If the proper cable tension can’t be obtained before the eyebolt runs out of adjustment, then do the following: a. Loosen the eyebolts but do not remove the nut. b. Loosen the clamps on the cable on both sides. c. Shorten the cable unti l there is tension on t he cable and tighten the clamps. d. Return to step 2. S TRAIGHTENING T HE T UBE 1. If tube is not st raight side-to-side: • If the tube is curved to the left, tighten the right -hand eyebolt and loosen the left-hand eyebolt on the long cable. • If the tube is curved to the right, tighten the left -hand eyebolt and loosen the right-hand eyebolt on the long cable. • Check the short cable for sla ck and tighten as necessary. • After adjusting the unit side- to-side, check that the tube still has a slight upward deflection at the discharge. 2. If the tube is sa gging at the discharge: • Lift the discharge end of t he auger with a front end lo ader or rest on a bin so that the tube has a slight upward def lection at the discharge to give the cable some slack. • Tighten the long cable’s eyebolts evenl y on both sides so the tube stays straight. • Tighten the cables so there is a slight upwards angl e on the discharge end. • Check the short cable for sla ck and tighten as necessary. Figure 5.7 Cable Adjustment

10. 2. S AFETY F IRST W HEATHEART - SA A UGERS 2.3. T RANSPORT S AFETY SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 10 4504156 R6 2.3. TRANSPORT SAFETY • Ensure tires are inflated to the ti re manufacturer’s re commended pressure. • Make sure that all light s and reflectors required by the local highway and transport authorities are in place, are functioning, and can be seen clearly by all overtaking and oncoming traffic. Check with local aut horities regarding transportation of agr icultural equipment on public roads. Obey all applicable laws and regulations. • Be sure the unit is hitched se curely to the towing vehicle. • Do not allow rider s while transporting. • Display a Slow Moving Vehicle (S MV) emblem when transporting below 15 mph (24 km/h). • Use hazard-warning flashers when trans porting with a tractor unless prohib- ited. • Keep to the right and yield the right-o f-way to allow faster traffic to pass. • Never transport faster t han the road terrain or cond itions will safely allow. • Use caution when turning corners or meeting traffic. • Use caution when approac hing height-limiting objects. • Be especially careful when transporting during times of limited visibility (rain, snow, fog, dusk, or at night ). If you can, wait for a more appropriate time to move the equipment. • Do not transport auger on a slope greater than 20°—t he auger may overturn. • The winch must be in the locked position. To lock, turn handle clockwise until you hear two clicks. 2.4. STORAGE SAFETY • Store in an area away from human activity. • Do not permit children to play on or around t he stored machine. 2.5. MAINTENANCE SAFETY • Shut off and disable the power sour ce before working on the machine. • Ensure service area is clean and dry. • Ensure electrical outlets and tools are pr operly grounded. • Use proper tools for the job and wear appr opriate safety gear.. • Ensure there is adequate lighti ng to perform the job safely. • Place chocks in front and behind the wheels to prevent the machine from roll- ing. • Use extra caution when cleaning and servicing augers because flighting edges can be sharp. • Follow proper procedures w hen mounting a tire on a ri m. If in doubt, have a qualified tire repair service pe rform the required maintenance. • Install and secure all guards afte r maintenance work is completed.

41. WARRANTY REGISTRATION Wheatheart congratulates you on your new equipment purchase. The warranty registration form must be filled out with in thirty (30) days from delivery date and sent to: Wheatheart Manufacturing Box 39 Rosenort, Manitoba, Canada, R0G 1WO CUSTOMER COPY (Retain this card for warranty and record purposes.) PRODUCT: DEALER’S NAME: SERIAL #: ADDRESS: DELIVERY DATE: OWNER’S NAME: PHONE #: ADDRESS: SIGNATURE: INVOICE #: PHONE #: (Please refer to invoic e # when filing claim) DEALER COPY (Retain this card for warranty and record purposes.) PRODUCT: DEALER’S NAME: SERIAL #: ADDRESS: DELIVERY DATE: OWNER’S NAME: PHONE #: ADDRESS: SIGNATURE: INVOICE #: PHONE #: (Please refer to invoic e # when filing claim) WARRANTY REGISTRATION (Must be filled out and returned to Wheatheart within 30 days of delivery.) OWNER’S NAME: DEALER’S NAME: ADDRESS: ADDRESS: PHONE #: PHONE #: SIGNATURE: (I acknowledge the product to be whole and in proper working order.) SIGNATURE: (I acknowledge the product to be whole and in proper working order. The owner has been given an operation manual and has been informed on proper operation and maintenance.) PRODUCT: SERIAL #: INVOICE #: DELIVERY DATE: GAS MOTOR SERIAL #:

22. 4. O PERATION W HEATHEART - SA A UGERS 4.4. O PERATION P ROCEDURE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 22 4504156 R6 4.4. OPERATION PROCEDURE 4.4.1. I NITIAL S TART -U P B REAK I N Your auger does not require an elaborate break-in. However, following a few simple tips during the init ial operation can add to the reliability and life of your machine. If any unusual noises or vi brations are encoun tered, determine the source, shut the auger off, lock out the power source, and adjust. If unsure of the problem or procedure, contact your local Wheatheart dealer. Important: When starting the auger fo r the first time, be prep ared for an emergency shutdown in case of exce ssive vibration or noise. 1. Ensure that you have comp leted the checklist on page 20. 2. If everything is satisfactory, prep are for a 60 minute oper ation at half speed. 3. Ensure that the intake hopper is correctly positioned. 4. Ensure that the PTO drive on th e tractor is in the OFF position. 5. Start the tractor and idle at low rpm. Slow ly engage the PTO drive. Note: The auger may run rough unt il the tube is polished. 6. Gradually begin feeding gr ain into the hopper, bringi ng the auger speed up to about 300 rpm. Do not over feed the hopper on initial loads; k eep the feed of grain at about half capacity. 7. After the auger tube is polished and runs fairly sm oothly, proceed to unload at full speed of 540 rpm. 8. Upon completion of the initial run, slow the auger down. Stop the auger when it is empty of grain. DANGER Rotating Auger Hazard Contact with rota ting flighting will result in amputation or severe laceration. DO NOT operate with guards removed or modified. Keep hands and feet away from rotating auger. Tie up long hair and remove jewelry. DO NOT wear loose-fitti ng clothing or items that could become caught. Shut off and lock out t he power source before unplugging or cleaning.

15. W HEATHEART - SA A UGERS 3. T RANSPORT & P LACEMENT SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 3.1. T RANSPORT P ROCEDURE 4504156 R6 15 3. Transport & Placement 3.1. TRANSPORT PROCEDURE The Wheatheart auger is de signed to be easily and c onveniently readied for transport. Follow th is procedure when converting the machine from operating to transport conf iguration. 1. Reconnect the hydraulic hose coupl ers to the tractor if disconnected. 2. Place PTO driveline in t he transport saddle and secure. 3. Remove all wheel chocks. 4. Raise the intake hopper off the ground. 5. Ensure the auger is clear of any obstructions before lowering. Warning: Before continuing, please re read the safety information re levant to this section at the beginning of this manual. Failure to follo w the safety instructions can result in serious injury, death, or property damage. DANGER Electrocution hazard: • This auger is not insulated. • Keep auger away from overhead power lines and devices. • Electrocution can o ccur without direct contact. • Fully lower auger before moving. Electrocution will result in serious injury or death. NOTICE Empty the auger before transport ing. Transporting a full auger will place excessive loads on the tube assembly, frame, axle assembly, hitch, and towing unit. If auger wheels are partially or fu lly buried in snow or grain, do not attempt to move auger until snow or grain has been cleared away from auger wheels. CAUTION Failure to secure the uni t prior to transporting could cause a seriou s hazard to the occupants of the towin g vehicle or other vehicles.

24. 4. O PERATION W HEATHEART - SA A UGERS 4.4. O PERATION P ROCEDURE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 24 4504156 R6 6. Stop the flow of ma terial (if applicable). 7. Correct the emergency before resuming work. The tube may be filled with ma terial if the machine is shut down inadvertently or for an emergency. It is recommended that you rest art with the following procedure: 8. With the power source lo cked out, remove as much of the grain as possible from the tube and intake using a piece of wood, vacuum cleaner, or other tool. Do not use your hands. 9. Start the tracto r and engage the PTO with the tractor idling. 10. Once the auger has been started, you may resume normal operation. 4.4.4. L OWERING & C OMPLETION 1. Run the unit to clean out the majority of the grain. 2. Lock out the power source. Refer to page 21 for procedure. 3. Disconnect the PTO dr iveline and raise the hopper off the ground. 4. Remove all supports and chocks. 5. Move the auger out of working po sition and lower into transport position. 6. If necessary, open the cleanout door on the boot and manually clean out grain using a piece of wood, va cuum cleaner, or other tool. Do not use your hands. Replace th e cleanout cover. 7. Lift the intake feed hopper into tr ansport position and clean out the grain from the hopper using a piec e of wood, vacuum cl eaner or other tool. Do not use your hands. 4.4.5. P OWER S WING / H YDRAULIC W INCH O PTION The power swing/hydraulic winch option (Figure 4.3) uses a common control valve (Figure 4.3) mounted to the intake hopper tube. Once the auger is raised in the working position with the wheels chocked, remove the locking pin securing the intake hopper to the hopper lift arm. Ensure the area in the path of the in take hopper is unobstruc ted. Use the winch control lever to lower the intake hopper to the ground. Unh ook the winch cable from the hopper. The inta ke hopper can now be pos itioned using the power swing control lever. Traction can be contro lled by adjusting the down pressure on the power swing w heels using the jack. NOTICE Always engage PTO with tracto r engine idling. Engaging PTO at high engine speed will result in equipment damage.

27. W HEATHEART - SA A UGERS 5. M AINTENANCE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 5.1. F LUIDS AND L UBRICANTS 4504156 R6 27 5. Maintenance 5.1. FLUIDS AND LUBRICANTS G EAR O IL Use SAE approved 90W or equivalent gear oil. G REASE Use SAE multi-purpose high-temperature grease with extreme pressure (EP) performance or SAE multi- purpose lithium-based grease. 5.2. MAINTENANCE INTERVALS For details of service, refer to Section 5.3. Warning: Before continuing, please re read the safety information re levant to this section at the beginning of this manual. Failure to follo w the safety instructions can result in serious injury, death, or property damage. NOTICE Do not modify equipment. Unauthorized modificati on may impair the f unction or safety of the equipment, coul d affect the life of the equipment, and will void your warranty. SECTION DAILY (8000 BU) PERIODICALLY (40,000 BU) BEFORE STORAGE AFTER STORAGE 3-5 YEARS (DEPENDING ON USE) VISUALLY INSPECT THE UNIT 5.3.1. Y Y INSPECT HYDRAULIC HOSE AND COUPLER 5.3.2. Y GREASE MACHINE 5.3.3. Y Y INSPECT HOPPER LIFT CABLE 5.3.4. Y SERVICE WINCH AND PULLEYS 5.3.5. Y SERVICE BOOT AND HOPPER CHAIN DRIVE • Y CHECK GEARBOX OIL LEVEL 5.3.7. Y CLEAN MACHINE 5.3.8. Y CHECK TIRE PRESSURE 5.3.9. Y Y REPACK WHEEL BEARINGS 5.3.10. Y TIGHTEN WHEEL BOLTS 5.3.11. Y SERVICE TRUSS CABLES 5.3.12. Y CHANGE GEARBOX OIL 5.3.13. Y

8. 2. S AFETY F IRST W HEATHEART - SA A UGERS 2.1. G ENERAL S AFETY SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 8 4504156 R6 2.1. GENERAL SAFETY Important: The general safety section includes instruct ions that apply to al l safety practices. Any instructions specific to a certain safety practice (e .g., assembly safety), can be found in the appropriate section. Al ways read the complete instructional sections and not just thes e safety summaries before doing anything with the equipment. YOU are responsible for the SAFE use and maintenance of your equipment. YOU must ensure that you and anyone else who is going to work around the equipment understands all pr ocedures and related SAFETY information contained in this manual. Remember, YOU are the key to safety. Good sa fety practices not only protect you, but also the people around you. Make these practices a working part of your safety program. • It is the equipment owner and the operator's responsib ility to read and under- stand ALL safety instructions, safety decal s, and manuals a nd follow them before assembling, operati ng, or maintaining the equipment. All accidents can be avoided. • Equipment owners must give instructions and review the in formation initially and anually with all personnel before allo wing them to operat e this product. Untrained users/operators expose t hemselves and bystanders to possible serious injury or death. • Use this equipment for its intended purposes only. • Do not modify the equipment in any way. Unauthorized modification may impair the function and/or safety, and coul d affect the life of the equipment. Any modification to the equi pment voids the warranty. • Do not allow children, spectators, or bystanders within the work area. • Have a first-aid kit avail able for use should the need arise, and know how to use it. • Provide a fire extinguisher for use in case of an accident. St ore in a highly vis- ible place. • Wear appropriate protective gear . This list includes, but is not limited to: • a hard hat •gloves • protective shoes with slip-resistant soles • protective goggles • hearing protection • For Powered Equipment: be fore servicing, adjusti ng, or repairing powered equipment, unplug, plac e all controls in neutral or off position, stop the engine or motor, remove ignition key or lock out power so urce, and wait for all mov- ing parts to stop.

32. 5. M AINTENANCE W HEATHEART - SA A UGERS 5.3. M AINTENANCE P ROCEDURES SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 32 4504156 R6 2. Make sure the gearbox is half full (center of cross s haft) and free of foreign objects. Gearbox should be level when checking or refilling. Do not overfill. 5.3.8. M ACHINE C LEANING 1. Clean out excess grain fr om auger tube, boot, and hopper. 2. Make sure water can drain from the auger tube and hopper and then wash the tube with a water hose or pressure washer until all dirt, mud, debris, or residue is gone. 3. Provide sufficient time for the water to drai n from the auger. 5.3.9. T IRE P RESSURE C HECK With a tire pressure gauge, check each tire to make sure it is between 18–24 psi (124 - 165 kPa). • Ensure tires are cold pr ior to checking pressure. 5.3.10. W HEEL B EARINGS R EPACK 1. Remove the wheel bolts and the wheels. 2. Remove the wheel bearing and pack with grease. Refer to page 27 for recommended grease. 5.3.11. W HEEL B OLT T IGHTENING 1. Clean wheel an d hub mounting surfaces to ensure there is no rust or debris. 1. Install the wheel and finger-tig hten the wheel bolts. Inspect to make sure the wheel is sitting fl ush with the hub. 2. Tighten the wheel bolts with a torque wrench to 80 ft-lb (±10 ft-lb) of torque. Tighten the wheel bolts in a diagonal pattern as shown in Figure 5.6. 5.3.12. C ABLE T IGHTENING The cables are prop erly adjusted when: • The tube is strai ght side-to-side. • The discharge end is deflected sightly upwards. Figure 5.6 Crisscross Pattern Note:

23. W HEATHEART - SA A UGERS 4. O PERATION SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4.4. O PERATION P ROCEDURE 4504156 R6 23 9. Lock out the trac tor and conduct a complete in spection of the auger following the checklist on page 20. Important: After the initial start-up and inspection, the auger should be shut down and inspected at least 3 more times during the first 10 hours of operation. 4.4.2. O PERATING W ITH A F ULL L OAD 1. Complete the checklist on page 20. 2. Place the intake hopper in its working position. 3. Make sure the PTO driv e is in the off position when starting the tractor. 4. Engage the PTO with the tractor idling to pr event unneeded stress on the drive components and shear bolts. 5. If everything is opera ting normally, start running gr ain through the auger and bring the auger up to spee d. Maintain a speed of 300–540 rpm for maximum efficiency and to reduce the chance of plugging. 4.4.3. S HUTDOWN N ORMAL S HUTDOWN 1. Near the end of the l oad, reduce the feed of gr ain and decrease the auger speed where possible. 2. Run the auger until the tube is empty. 3. When the auger is clear of grain, disengage the PTO. 4. Shut down and lock out the power source. E MERGENCY S TOP / F ULL -T UBE R ESTART Although it is reco mmended that the machine be em ptied before stopping, in an emergency situation: 5. Stop or shut down the power source immediately. NOTICE Do not run an empty auger at high speed; this results in excessive wear. NOTICE Foreign objects can damage the auger. Remove any obstructions from the intake and discharge areas before operating the unit. NOTICE Prolonged operation of an empty auger will cause unnecessary wear.

17. W HEATHEART - SA A UGERS 3. T RANSPORT & P LACEMENT SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 3.2. P LACEMENT P ROCEDURE 4504156 R6 17 b. Ensure there is no more slack in the chain than requ ired for turning. c. When not in use, store the safety chain in a clean , dry place. Replace the safety chain if one or more links or end fittings are brok en, stretched, or otherwise damaged or deformed (Figure 3.3). 3.2. PLACEMENT PROCEDURE Important: Wheels must be free to move when raising or lowering the auger. 1. Disconnect PTO driv eline from tractor. 2. Position towing hitch a nd secure (Figure 3.5). Important: Always use a safety c hain when transporting the auger. 3. Extend wheels (1081, 1091, and 13” models only) as shown in Figure 3.4 4. Check that hydraulic hoses and connections are undamaged and free from leaks. Figure 3.5 Note: Replacement hose and hose ends must have a minimum st rength of 2500 psi (17200 kPa) working pressure. 5. Place the auger on a firm, level surface. WARNING Maximum transport speed: Do not transport fast er than 15 mph (24 km/h), or faster than road conditions allow. A weight imbalance between the towing vehicle and the machi ne could reduce your vehicle’s stability, handling, and braking ability, and lead to an upset or collision. Figure 3.4 Wheel Extended

31. W HEATHEART - SA A UGERS 5. M AINTENANCE SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 5.3. M AINTENANCE P ROCEDURES 4504156 R6 31 1. Remove chain cover pl ate from the boot or hopper. 2. Check chain slack. • Chain slack is checked at the midpoint of the longest span. It should be no more than 1/4” (6 mm). Note: The Hopper has 2 chains, 1 for each flighting. 3. Adjust the chain slack. a. For the Boot: loosen the 4 bolts of the lower bearing and adjust the chain slack (Figure 5.3). If the chain can’t be tightened enough, remove a link from the chain. If the chain will not fit with one link removed, add a hal f link to the chain and replace. b. For the Hopper: loos en the 2 bolts of the flighting bearing on the side that needs adjustment and set the chain slack (Figure 5.4). If the chain can’t be tightened enough, remove a link from the chain. If t he chain will not fit with one link removed, add a hal f link to the chain and replace. 4. Lightly oil the chain. 5.3.7. G EARBOX O IL L EVEL A CCESSING G EARBOX Upper Gearbox • Flip up safety di scharge door or open round service door and service gearbox as required. Lower Gearbox • Open round servic e door and service gearbox as required. C HECKING O IL L EVEL 1. Remove oil filler plug as shown in Figure 5.5. NOTICE Improper adjustment of chain will result in premature wear. Figure 5.3 Boot Chain Drive Figure 5.4 Hopper Chain Drive Figure 5.5 Oil Filler Location Note: Note:

7. W HEATHEART - SA A UGERS 2. S AFETY F IRST SA 1061, 1071, 1081, 1091, 1371, 1381, 1391 4504156 R6 7 2. Safety First The Safety Alert symbol to the left i dentifies important safety messages on the product and in the manual. W hen you see this symbol, be alert to the possibil- ity of personal injury or death. Follow the instruct ions in the safety messages . Why is SAFETY important to you? Three big reasons: • Accidents disable and kill. • Accidents cost. • Accidents can be avoided. SIGNAL WORDS Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE with the safety messages. The appropriate signal word for each message has been selected using t he definitions belo w as a guideline. The Safety Alert symbol means ATTE NTION, BE ALERT!, YOUR SAFETY IS INVOLVED. DANGER Indicates an im minently hazardous situation that, if not avoi ded, will result in serious injury or death. WARNING Indicates a hazardous si tuation that, if not avoided, could result in serious injury or death. CAUTION Indicates a hazardous si tuation that, if not avoided, may result in minor or moderate injury. NOTICE Indicates a potentiall y hazardous situat ion that, if not avoided, may result in property damage.

Views

- 11877 Total Views

- 8956 Website Views

- 2921 Embeded Views

Actions

- 0 Social Shares

- 0 Likes

- 0 Dislikes

- 0 Comments

Share count

- 0 Facebook

- 0 Twitter

- 0 LinkedIn

- 0 Google+

Embeds 6

- 11 www.grainland.com.au

- 2 odoo.grainland.com.au

- 7 grainland.com.au

- 167 www.google.com

- 11

- 1 m.baidu.com

-

Wheatheart 10" & 13" Swingaway Auger Brochure

4286 Views . -

Wheatheart 10" Swingaway Auger Specifications

4082 Views . -

Wheatheart 13" Swingaway Auger Specifications

3947 Views . -

Wheatheart 10 & 13" Swingaway Auger Parts List

12074 Views .

-

Farm King 10" Swingaway Auger Parts List & Manual

26397 Views . -

Wheatheart Post Pounder Manual

21216 Views . -

Farm King 13" Swingaway Auger Parts List & Manual

21018 Views . -

Farm King 16:104 Swingaway Auger Parts List & Manual

18167 Views . -

Wheatheart 10 & 13" Swingaway Auger Parts List

12074 Views . -

Wheatheart Conventional Auger Parts List

11413 Views . -

REM Grain Vac 2700 Parts List

11221 Views . -

Spitfire Wheat Fact Sheet

11047 Views . -

Wheatheart Conventional Auger Manual

10450 Views . -

Honda GX630 GX660 & GX690 Manual

9993 Views . -

Winter Crop Variety Sowing Guide 2015

8593 Views . -

Farm King 10" Swingaway Manual & Parts List (2012)

8498 Views . -

Lancer Wheat Fact Sheet

8342 Views . -

REM Grain Vac 3700 Parts List

7786 Views . -

Kohler CH18 -CH750 Service Manual

7765 Views . -

Batco Field Loader Operation

7719 Views . -

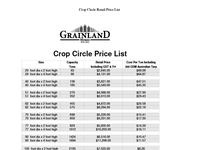

Crop Circle Price List

7702 Views . -

Suntop Wheat Fact Sheet

7601 Views . -

Farm King 36,41 & 51 foot Conventional Auger Manual

7596 Views . -

Noxious & Environmental Weed Control

7571 Views .