1. Belt Conveyors & Accessories

3. batcomfg.com Batco started in 1992 and later became the founding company of AGI. Humble beginnings had Batco building two-wheel carts; fast forward to present day where Batco manufactures an extensive line of portable and stationary belt conveyors used in storage and handling facilities for grain and fertilizer. Over the past two decades, Batco has grown their sales through innovative products and a strong focus on customer needs and services. Outgrowing their 33,000 square foot facility, in 2013, Batco moved into an 114,000 square foot facility featuring lean manufacturing processes, robotic welding and a state-of-the-art powder coat paint system which will increase quality, productivity and has the potential to double capacity. The improved facility provides more space to accommodate robotic welding, delivering more consistent and reliable production, as well as lean manufacturing, which ensures efficient and quick production to meet customer demand. Powder coating is an advanced method of applying a protective finish. The powder used for this process is a mixture of finely ground particles of pigment and resin, which is sprayed onto the surface of our products. The result is a much thicker coating with a classic vibrant Batco orange finish that is more durable and long lasting than conventional liquid paint.

2. PINCH S-DRIVE Batco Belt Conveyors and equipment are built tough to perform, yet designed and engineered for gentle handling of delicate crops, seeds and commodities. Low Horsepower Batco’s unique design requires half the horsepower of screw augers, saving energy and freeing up larger tractors for other purposes. Clean Convenience Batco’s unique design requires half the horsepower of screw augers, saving energy and freeing up larger tractors for other purposes. High Capacity All Batco Conveyors are designed and built for high capacity and performance at a maximum height of 30°. Capacity increases as the angle of elevation decreases. See specifications for model performance. Low Maintenance/Long Wear Engineered, designed and built for rugged, long-lasting performance with heavy duty features like our quality rubber belting, rated at 3,000 hours. Gentle Handling Specialty crops, seed and some commodities are very susceptible to impact damage caused by conventional grain handling systems. A Batco Belt Conveyor minimizes impact damage and helps protect grade quality and germination performance of seed. Not recommended on oil seeds. Pinch roller pinches belt onto drive roller to eliminate slipping An affordable option unique to Batco, is the Pinch Top Drive. The pinch roller system at the top end ensures positive belt traction. Electric or hydraulic Pinch Top Drive options are available. PINCH TOP DRIVE Batco’s unique Pinch S-Drive is available on all series (not transfers or pit stops) and eliminates slippage by making it easy to set and maintain belt traction. The spring take up helps to maintain tension while less friction minimizes damage to the conveyor belt, also invoking minimal stress on the bearings. Gas or electric Pinch S-Drive options available.

5. batcomfg.com SERIES 2000 SERIES 2400 14" Tube 20" Belt 14" Tube 23.5" Belt • Capacity rated up to 9,000 bu/hr • Available in lengths from 35' to 120' • 14" diameter, 12-gauge tube • Capacity rated up to 14,000 bu/hr • Available in lengths from 65' to 120' • 14" diameter, 12-gauge tube FEATURES • A-frame undercarriage on 35' – 55' lengths • Dual cylinder hydraulic scissor lift on 65' – 95' lengths • Triple cylinder hydraulic scissor lift on the 105' – 120' models • Cable trussing on 55' – 110', steel trussing on the 120' • Heavy-duty, 1 15/16" shafts and industrial bearings DRIVE OPTIONS • Pinch S-Drive • Electric • PTO (side or front) • Top Drive (35' only) • Electric 150 0 SERIES 2400 SERIES 2000 2400 2000 2400

6. FIELD LOADERS 1300 1500 1800 2400 Batco Field Loaders include all the benefits of the standard hopper Belt Conveyors but feature an extended low-profile hopper, with unique collapsible design. • Optional self-propelled kit available on all models SERIES 1300 10" Tube 13" Belt SERIES 1500 10" Tube 15" Belt SERIES 1800 14" Tube 18" Belt SERIES 2400 14" Tube 23.5" Belt • Capacity up to 4,500 bu/hr • 35' or 45' lengths available • Capacity up to 6,000 bu/hr • 35' or 45' lengths available • Capacity up to 8,000 bu/hr • 35' length available • Capacity up to 14,000 bu/hr • 35' length available ALSO AVAILABLE 2435 Railcar Unloader with lower profile hopper to suit above-track loading • Available with gas or electric Pinch S-Drive • Capacity up to 14,000 bu/hr • Ultra low hopper = 4" hopper height FIELD LOADER DRIVE OPTIONS 1300 1500 1800 2400 • Pinch S-Drive • Gas • Electric • Pinch Top Drive • Electric • Hydraulic (1300, 1500 & 1800)

7. batcomfg.com SWING AWAY 1500 2000 2400 A low-profile transfer conveyor/swing away with collapsible hopper is available on the 1500, 2000 and 2400 series conveyors for the 65' – 120' models. • Center mounted CV PTO shaft with gearbox drive system • Standard with hydraulic winch • Hydraulic drive swing • Requires approximately 12 GPM on 1500 series, 18 GPM on 2000 and 2400 series LOW PROFILE TRANSFERS 1300 1500 1800 • 7 ½" hopper clearance; 9" clearance at transition • Discharge height – 28" • 30" x 56" collapsible hopper on 1314 LP & 1814 LP • 30" x 75" collapsible hopper on 1515 LP • Hydraulic, electric or gas drive options PIT STOP 1800 2400 • Quick, convenient unloading • Gentle handling and fast setup • Low, 7 ½" clearance • 8" x 12" easy access dump platform • Large, 32" x 114" hopper • Hydraulic lift on transport wheels • Discharge height – 28" • Overall length – 25' on 1800 series – 27' on 240 0 series • Hydraulic, gas or electric drive options • Optional self-propelled kit available LOW PROFILE TRANSFERS PIT STOP

4. SERIES 1300 10" Tube 13" Belt • Capacity rated up to 3,500 bu/hr • Available in lengths from 35' to 55' • 10" diameter, 14-gauge tube FEATURES • A-frame undercarriage • Cable trussing on the 55' Model • Optional self-propelled kit available DRIVE OPTIONS • Pinch S-Drive (55' only) • Gas • Electric • PTO • Top Drive (30'- 45') • Hydraulic • Electric SERIES 1500 10" Tube 15" Belt • Capacity rated up to 6,000 bu/hr • Available in lengths from 35' to 100' • 10" diameter, 14-gauge tube • 12-gauge tube for the first 30' on the 55'-100' models FEATURES • A-frame undercarriage on 30' - 55' lengths • Hydraulic scissor lift on 65' - 100' • Offers greater reach and bin clearance • Cable trussing on the 55' – 100' models • Extendable axles on 85' – 100' models • Optional self-propelled kit available DRIVE OPTIONS • Pinch S-Drive (55’-100’) • Gas • Electric • PTO (side or front) • Top Drive (30' & 35') • Hydraulic • Electric • Pinch Top Drive (40' & 45') • Hydraulic • Electric • Weather guards are standard on all conveyors • Maximum service height at 30-degrees • All belts are made of 2-ply Chevron, with nylon slider back • Plastic hood and collapsible canvas hoppers provides excellent cushioning for fragile materials BELT CONVEYORS 1300 1500 2000 2400 Optional Self-Propelled Kit

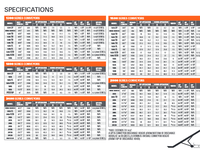

8. 1300 SERIES CONVEYORS MODEL BELT LENGTH WEIGHT LBS UP-OPERATION DOWN-OPERATION WIDTH HP PTO HP ELEC HP GAS HP HYD. (Cu.in.) A B A B 1314 LP 28'4" 526 N/A N/A 2.9 5.5 3 N/A 5 HP 6.5 HP 4.5 (H SERIES) SWING TRANSFER 34'6" 570 N/A N/A N/A N/A N/A N/A 5 HP N/A 4.5 (H SERIES) 1330 TD 58'8" 1409 13.5 9.5 9.6 11.1 7.5 N/A 5 HP N/A 5.9 (H SERIES) 1335 TD 68'8" 1506 16.3 11.3 10.8 12.3 7.5 N/A 5 HP N/A 5.9 (H SERIES) 1340 TD 78'8" 1603 18.3 14.5 9.5 15.1 7.5 N/A 7.5 HP N/A 5.9 (H SERIES) 1345 TD 88'8" 1700 21.3 18.4 12 19 7.5 N/A 7.5 HP N/A 5.9 (H SERIES) 1335 FL 81' 1826 16.9 16.2 13.2 18.3 7.5 N/A 7.5 HP 27 HP N/A 1345 FL 101' 2011 21.9 20.6 13.2 22 7.5 N/A 7.5 HP 27 HP N/A 1335 FLTD 76'6" 1500 16.9 13.6 11.9 14.6 7.5 N/A 7.5 HP N/A 6.2 (2000 SERIES) 1345 FLTD 96'6" 1730 21.9 19.5 12.7 19.4 7.5 N/A 7.5 HP N/A 6.2 (2000 SERIES) 1355 113'10" 2268 26.2 22.2 14.9 23.6 9 30 HP 7.5 HP 27 HP N/A 1500 SERIES CONVEYORS MODEL BELT LENGTH WEIGHT LBS UP-OPERATION DOWN-OPERATION WIDTH HP PTO HP ELEC HP GAS HP HYD. (Cu.in.) A B A B 1515 LP 30'8" 642 N/A N/A 2.8 6.2 3.8 N/A 5 HP 9 HP 5.9 (H SERIES) SWING TRANSFER 34'6" 700 N/A N/A N/A N/A N/A N/A 7.5 HP N/A 5.9 (H SERIES) 1530 TD 60'2" 1483 14 10.3 9.3 11.6 7.5 N/A 7.5 HP N/A 6.2 (2000 SERIES) 1535 TD 70'2" 1582 16.8 12 10.7 12.8 7.5 N/A 7.5 HP N/A 6.2 (2000 SERIES) 1540 TD 80'2" 1681 18.8 15.2 11.2 15.5 7.5 N/A 7.5 HP N/A 6.2 (2000 SERIES) 1545 TD 90'2" 1780 21.5 19.1 11.9 19.5 7.5 N/A 10 HP N/A 6.2 (2000 SERIES) 1535 FL 85' 1950 17 17.3 12.5 19.1 7.5 N/A 10 HP 27 HP N/A 1545 FL 105' 2275 22.9 23.7 12.4 25.8 7.5 N/A 15 HP 27 HP N/A 1535 FLTD 80'5" 1630 17 15.6 11.3 17 7.5 N/A 10 HP N/A 6.2 (2000 SERIES) 1545 FLTD 100'5" 1936 22.9 21.4 13.2 22 7.5 N/A 15 HP N/A 6.2 (2000 SERIES) 1555 115'3" 2354 26.3 22.2 14.9 23.6 9 30 HP 10 HP 27 HP N/A 1565 135'6" 2997 31.4 22.4 11.6 26.1 11 30 HP 15 HP 27 HP N/A 1575 155' 3252 36.6 30.9 12.6 36.2 11 40 HP 20 HP 27 HP N/A 1585 175' 3734 41.7 35.2 14.2 41.7 11.3 40 HP 20 HP 35 HP N/A 1590 185' 3850 44.2 39.5 14.9 46.7 11.3 50 HP 25 HP 35 HP N/A 15100 205' 4450 49 39.7 13.5 48.3 11.3 50 HP 25 HP 35 HP N/A 1800 SERIES CONVEYORS MODEL BELT LENGTH WEIGHT LBS UP-OPERATION DOWN-OPERATION WIDTH HP PTO HP ELEC HP GAS HP HYD. (Cu.in.) A B A B 1814 LP 29' 840 N/A N/A 3 5.8 3.8 N/A 7.5 HP 9 HP 6.2 (2000 SERIES) 1835 73'9" 2246 15.5 15.5 11 17.1 7.5 25 HP 10 HP N/A N/A 1835 FL 86'11" 2740 16.9 17.5 13.3 18.2 7.5 25 HP 10 HP N/A N/A 1835 FLTD 81'2" 2200 16.9 15.9 13.7 15.1 7.5 N/A 10 HP N/A 6.2 (2000 SERIES) 1845 93'9" 2532 21.1 18 12.5 22 7.5 30 HP 10 HP N/A N/A 1855 113'9" 3076 26.1 23 15.4 24.3 10.3 40 HP 15 HP N/A N/A PITSTOP 47' 2970 N/A N/A 2.8 4.5 7.9 N/A 7.5 HP N/A 6.2 (2000 SERIES) 2000 SERIES CONVEYORS MODEL BELT LENGTH WEIGHT LBS UP-OPERATION DOWN-OPERATION WIDTH HP PTO HP ELEC HP GAS HP HYD. (Cu.in.) A B A B SWING TRANSFER 41'6" 900 N/A N/A N/A N/A N/A N/A 7.5 HP N/A 6.2 (2000 SERIES) 2035 77'10" 2765 16.1 16.9 10.7 17.4 7.5 40 HP 15 HP N/A N/A 2035 TD 71'3" 2145 16.1 13.4 10.7 14 7.5 N/A 15 HP N/A N/A 2045 97'10" 3098 20.8 21.4 13 22.7 7.5 40 HP 15 HP N/A N/A 2055 117'10" 3650 26.1 24.7 13.8 24 10.3 50 HP 20 HP N/A N/A 2065 137'10" 4826 31.1 22.3 12.2 25.3 *11.6 60 HP 25 HP N/A N/A 2075 157'10" 5126 36.3 31.1 13.7 35.3 *11.6 60 HP 30 HP N/A N/A 2085 177'10" 5868 40.7 32.1 12.7 38.1 *11.6 70 HP 30 HP N/A N/A 2095 197'10" 6127 46.4 40.7 14.4 48 *11.6 80 HP 40 HP N/A N/A 20105 217'10" 7990 51.1 39.6 16.6 49.1 *11.6 80 HP 40 HP N/A N/A 20110 227'10" 9155 54 44.4 17.1 54.1 *11.6 100 HP 50 HP N/A N/A 20120 247'10" 9430 59.3 52.1 18.4 63.8 *11.6 100 HP 50 HP N/A N/A 2400 SERIES CONVEYORS MODEL BELT LENGTH WEIGHT LBS UP-OPERATION DOWN-OPERATION WIDTH HP PTO HP ELEC HP GAS HP HYD. (Cu.in.) A B A B SWING TRANSFER 45'3" 1300 N/A N/A N/A N/A N/A N/A 10 HP N/A 8.0 (2000 SERIES) 2435 FL 94'6" 3350 17.3 16.2 14 16.8 7.5 N/A 20 HP 35 HP N/A 2435 FLTD 87'3" 2700 17.3 15.8 14.1 15 7.5 N/A 20 HP N/A N/A 2465 141'2" 5081 32.1 23.4 12.5 26 *11.6 60 HP 25 HP N/A N/A 2475 161'2" 5396 36.1 32 14.3 35.8 *11.6 70 HP 30 HP N/A N/A 2485 181'2" 6153 42.3 32.6 13.7 38.6 *11.6 80 HP 30 HP N/A N/A 2495 201'2" 6630 47.1 41.5 14.9 48.5 *11.6 80 HP 40 HP N/A N/A 24105 221'2" 8305 52.5 40.7 16.3 49.7 *11.6 90 HP 40 HP N/A N/A 24110 231'2" 9495 53.9 45.3 17.1 54.7 *11.6 100 HP 50 HP N/A N/A 24120 251'2" 9770 60 53.4 18.4 64.6 *11.6 120 HP 50 HP N/A N/A 2400 PITSTOP 52'10" 3260 N/A N/A 3 5.3 7.9 N/A 10 HP 27 HP 8.0 (2000 SERIES) Box 1750 Swift Current, Saskatchewan Canada S9H 4J8 877.667.7421 info@batcomfg.com batcomfg.com SPECIFICATIONS *AXLE EXTENDS TO 14.8' A UP IS CONVEYOR DISCHARGE HEIGHT (FROM BOTTOM OF DISCHARGE HOOD) AT 30 DEGREES | A DOWN IS OVERALL CONVEYOR HEIGHT (FROM TOP OF DISCHARGE HOOD) Custom Configured Batco Conveyors can be “Custom Configured” to fit almost any requirement Depending on the model, choose from gas, electric, PTO or hydraulic drive options. The unique Batco Pinch S-Drive can be mounte d almost anywhere along the tube – at the lower end to accommodate PTO drive, or higher on the tube for other drives to allow longer reach into bins. An electric top drive is also available for models under 45 feet. Optional swing hoppers, portable transfers or self-propelled kits add versatility. Most Batco models are available in corrosion resistant stainless steel to accommodate bulk material handling. Advanced custom belt conveyor configurations can be accommodated by the factory. See your dealer for details. REMEMBER! Safety is everyone’s business! Some items shown with safety shieldsremoved for clarity. Do not operate with safety shields removed. Do not modify. Use only for intended purpose. Read manual before operating. • Hydraulic Systems: H Series requires 12-16 gal/min; 2000 Series requires 16-20 gal/min • 1314 LP: 6 1/2 HP Honda comes with 6:1 gear reduction • 1814 LP/1515 LP: 9 HP Honda comes with 6:1 gear reduction • Custom under bin systems and stationary conveyors are also available in 8", 10" and 14" diameter tubes