5.

1. X Series Augers

3. Square one bolt flight connection provides positive transfer and improved performance. Flight Connection Continuous 10 GA ribbon welded to flighting edge where most of the wear occurs. Standard on all X Series augers at critical grain transfer points. Wear Edge Stabilizes the lower scissor and keeps the main auger straight regardless of which side the swing Hopper is on. Also adds strength to the frame, keeping the spout level. Stabilizer Bracket Can be quickly changed from the left or right hand side of the auger to give the operator the convenience of unloading on both sides. Hopper Lift Arm Maintains maximum capacity when the auger is raised to its highest position. Tapered Boot The 10.5" low profile hopper has left and right hand flighting with a 6" one piece rubber extension to prevent grain splashing. For easy service, the u-joints have external grease points and the chain cover is hinged for quick inspection. Swing Hopperwith Solid Tires Removable boot flight with wear edge to improve durability of lower flighting. Removable Boot Flight

2. www.wheatheart.com Wheatheart uses a premium powder coat on all painted parts for durability and a great looking finish. Powder Coat Paint Removable end plate for easy access to flighting. Upper Tube Welded heavy duty angle flanges for rigid tube connections, additional bolts are added to the top and bottom for reinforcment. Angle Flange • Wide stance for stable operation at the bin. • Adustable axle extensions for reduced transport width. Extendable Axles Trussing provides maximum strength and stability at all heights. Steel trussing on 84' & 94' units increase tube rigidity and ensure smooth operation. Steel Trussing • Square tube design with dual cylinder lift system for all bin and storage applications. • Low transport height for easy towing. Scissor Lift Frame

4. www.wheatheart.com 1000 PTO Drive Allows operation with high horsepower tractors (reverser included). Reverser Kit Ability to reverse all flighting. Allows quick and easy clean out (shown with guards removed for clarity). Flex Spouts Directs grain flow – reduces spillage. Available in poly plastic or galvanized metal. Corn Screen Up to 4' long. Available on all models. Factory installed on the swing hopper tube. Right Angle Drive Assists operation in limited space situations. Allows a full arc on opposite side of tractor. Add These Optional Features Portable Drive Over Pit Ideal for high volume harvesters. • Available in 10" and 13" sizes • Hydraulically or electrically powered • Low profile ( 7 3 ⁄ 8 "operating deck) minimal maintenance design • Large side hopper accommodates side discharge grain cart • Spring assisted ramps and rear mounted hydraulic axle for easy transport • Discharge height of 27" It’s the auger you asked for. Our latest innovation – the X Series auger features over 75 new performance enhancements. With a precision engineered, commercial-strength frame and a redesigned hopper, the X Series offers unmatched serviceability and extreme durability. In order to design the most robust auger we’ve ever built, we utlized our world-class manufacturing facility and highly skilled research and development team. The X Series was 12000 R&D hours and four years in the making, employing a dedicated testing centre for auger capacity and durability testing. Our specialized bin simulation test center features an 80' structure with access points every 10' for elevation testing at multiple heights. We put the X Series through the paces, with multiple commodities and weighing station for accuracy and electrical and PTO power for testing all auger applications. We are confident that the X Series will not only meet, but surpass your expectations for durability and performance.

6. P.O. Box 39, Rosenort, Manitoba, R0G 1W0 Toll Free: 1-866-467-7207 Web: www.wheatheart.com Email: sales@wheatheart.com General Specifications Height and Reach Specifications (Specifications and design are subject to change without notice) A C D B ! Safety First! Wheatheart augers are designed with operator safety in mind and incorporate many safety features. Everyone operating an auger must read and understand the operator's manual and safety decals before attempting to operate the unit. Do not modify this implement in any way. Use only for intended purposes. Keep all safety shields in place while operating. Never operate with any safety shields or guard removed or modified. Never transport the unit in a raised position. Check overhead before raising. Never attempt to service the auger while it is running. Keep children, pets and untrained personnel away from work area. We know you work long and hard, especially during harvest. FIRST! Please take the time to put safety first: Heights measured from bottom of auger spout to ground. Specifications X1374 X1384 X1394 Tubing Gauge 12ga Tube Connectors Heavy Duty 1/4" Angle Flange Main Flighting 11-3/4" OD x 1/4" Stretched + Welded (Wear Edge at Critical Transfer Points) Reinforced flight (Wear-Edge) Hopper, Boot and Incline Tube Flighting Shaft High Strength 3" OD x 11ga Tubing Square Flight Connection Upper Bearing 1-3/4" Pillow Block Greaseable ball bearing Lower Bearing 2" Pillow Block Greaseable ball bearing Tube Trussing 3/8" Aircraft Type Galv Steel Cable 2-1/2" Steel Tube Hydraulic Lift Two 4" Single Acting Cylinders Two 4-1/2" Single Acting Cylinders Undercarriage 4" x 10" Scissor-Lift Axle 4" x 4" Square Tubing Hub 6 Bolt Automotive Type Tires 16" PTO Shaft 55R Constant Velocity w/ 2-bolt Shear Parking Jack 5000 lb. Side Wind Sprocket & Chain #80 Low Profile Hopper Height 10-1/2" PSI Required to Raise Auger 1500 1950 2050 HP Required (w/ Dry Wheat) 125 135-155 145-165 Wheel Tread 146"-182" Transport Height 11' 7" 12' 12' Height A Height B Height C Height D lowered halfway raised lowered halfway raised lowered halfway raised lowered halfway raised X1374 9' 2" 25' 8" 48' 8" 38' 7" 36' 7" 28' 1" 4' 6" 12' 7" 24' 4" 38' 7" 36' 9" 29' 7" X1384 9' 5" 30' 55' 43' 9" 41' 34' 4' 6" 15' 9" 27' 5" 43' 9" 41' 3" 34' 8" X1394 9' 2" 34' 4" 60' 1" 49' 46' 3" 37' 7" 4' 6" 17' 1" 30' 49' 46' 6" 38' 5"

Views

- 3793 Total Views

- 2896 Website Views

- 897 Embeded Views

Actions

- 0 Social Shares

- 0 Likes

- 0 Dislikes

- 0 Comments

Share count

- 0 Facebook

- Twitter

- 0 LinkedIn

- 0 Google+

Embeds

3

-

8

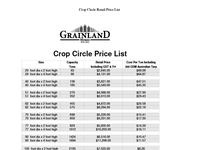

www.grainland.com.au

-

7

odoo.grainland.com.au

-

5

grainland.com.au